Borosilicate Glass Manufacturer

Borosilicate glass manufacturer: tailored solutions for your needs

Cambridge Glassblowing is your trusted partner in the world of borosilicate glass manufacturing. With over four decades of experience in providing glass fabrication services, we are proud to be a leading name in the global borosilicate glass market, specializing in high quality borosilicate glass products tailored to your unique requirements. Let’s talk about the world of borosilicate glass, its myriad benefits, and how Cambridge Glassblowing stands out as your premier choice among borosilicate glass suppliers for laboratory glassware and beyond.

Borosilicate Glass Manufacturing

As one of the leading scientific laboratory glassware manufacturers, we understand the significance of precision and quality when it comes to borosilicate glass fabrication. Our advanced design and manufacturing techniques are driven by cutting-edge glass technology. We take pride in offering a borosilicate glass fabrication service that set us apart in the industry:

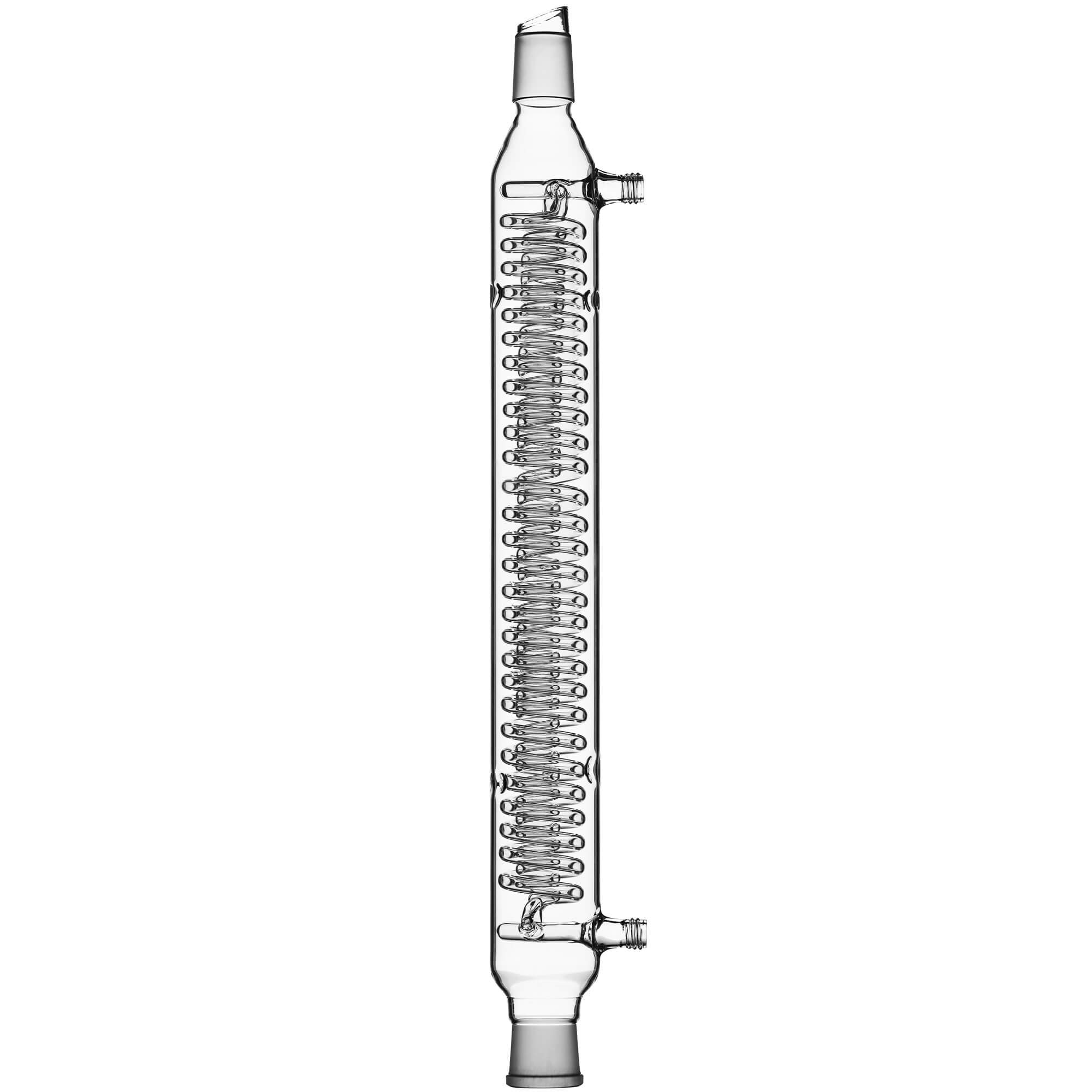

- Customization: custom borosilicate glass starts at the design phase, our on-site CAD drawing facilities enable us to turn your ideas into reality. Whether you need a simple borosilicate glass tube, precision glass component, or a complex glass system, we can create tailored solutions to match your concepts.

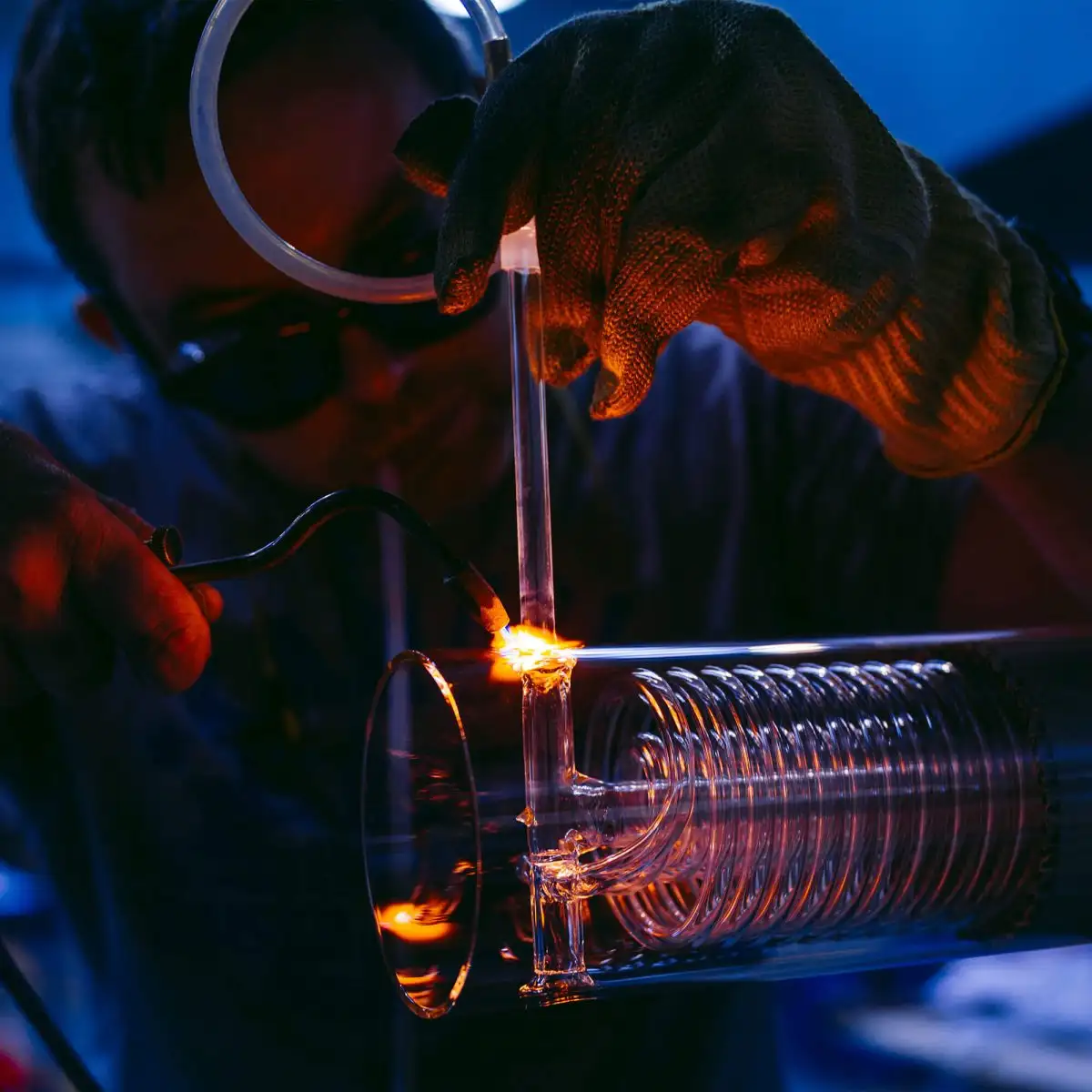

- Scientific glassblowing process: the scientific glassblowing is quite different, instead of working with a glass drawn direct from a furnace, scientific glassblowers use precision drawn glass tubes as their starting material. These borosilicate tubes and rods can then be cut, shaped, and fused together to create the desired technical glass products.

- What is the borosilicate glass fabrication process: tubes and rods can be prepared by cutting and grinding. A fuel gas and oxygen are burned to create a flame with a temperature of around 2500oC and this is used to soften the glass. The softened glass can then be manipulated to create the desired shape. By using very localised heat, the edges of two parts can be heated to a temperature where the glass will flow together to create a seamless join.

- Borosilicate glass: tubes and rods are manufactured from 3mm diameter to a very substantial 465mm diameter, many of these are produced in multiple wall thicknesses. We can shape, and fuse parts seamlessly together, fabricating a virtually unlimited spectrum of borosilicate glass products. Whether it’s for a laboratory or industrial application.

- Borosilicate glass annealing: it is essential that all borosilicate glassware is correctly annealed at the end of manufacturing. This removes residual stress which builds up within the glass during the manufacturing process. Failure to do this correctly will leave the item prone to failure, especially where heat or physical forces may be applied when in use. The annealing process is not a one size fits all approach. Thicker and heavier items require a different heating and cooling profile compared to lighter objects. Finished products are heated at a controlled rate in a kiln to a temperature of 565 oC, once at temperature, the stress in the glass begins to relax again larger items need to be held at temperature for longer. The temperature is then slowly reduced following a controlled cooling profile suitable for the contents of the kiln. All our kilns are equipped with calibrated digital controllers which can store multiple pre-defined profiles which are suitable for almost every scenario. This helps the team ensure that 100% of items are perfectly annealed.

- Diverse capabilities: we are proud to have both the skills and facilities to work with the full range of materials available and are fortunate the have almost all sizes held in stock to allow a rapid response to urgent demands. In addition to glass tubes, pre-made components such as glass threads, tapered joints, glass ball joints, valves and filter discs provide a cost-effective solution to create interchangeable scientific glassware that can link to other systems.

- Quality: the production of precision technical glass products requires much more than equipment and skilled people. Having the underlying strong processes and controls in place is what allows us to deliver exceptional custom glass fabrication, time after time.

Borosilicate glass applications

We produce borosilicate glass products for many scientific and industrial applications, here a few examples of the seeming endless list of uses.

- Chemical research

- Chemical manufacturing

- Environmental testing

- Optical analysis and monitoring

- CO2 Lasers

- Food safety

- Recycling

- Food, flavours, fragrances

- Lighting and displays

- Fire safety

- Sanitary drainage

- Solar PV and other renewables

What makes borosilicate glass such a popular choice for so many applications?

Borosilicate glass has a unique combination of properties which make it the ideal choice. Its transparency and clarity immediately stand out compared to most plastics. This is then coupled with excellent thermal and chemical resistance properties which make it unmatched by alternatives. Another less obvious property is its ability to be shaped, moulded, fused and joined together to produce a totally seamless product. Two pieces of glass flow together like mixing two glasses of water, once joined together they are essentially one thing. The way it is worked makes it extremely cost effective to produce small quantities of unique items for prototyping or specialist applications where other material would require expensive moulds or tools.

What is borosilicate glass?

Borosilicate glass was developed in the late 19th century to overcome some specific heat related issues the was a characteristic of standard glass. The inventors discovered that by adding up to 12% Boric Oxide, the coefficient of expansion and its softening point could be dramatically improved. Further developments over the next few decades eventually resulted in a standard material known as borosilicate 3.3 (the 3.3 relating to its coefficient of expansion). This product is now defined within ISO 3585:1998 Standard.

When connecting glass components together it is essential that you ensure that the glass does conform to the same standard as mismatched expansion rates can lead to possible failures.

Unfortunately, not all borosilicate glass manufacturers make their glass to fully adhere to the standard, it can be hard to tell them apart as they appear similar. To ensure your safety and performance of the product it is wise to fully understand the origins and be totally confident that your supplier only offers genuinely compliant products.

Cambridge Glassblowing sources all its raw materials from Europe’s two main glass producers and can, if required, provide certificates of conformity and if essential can even provide batch traceability. When you work with us you can be 100% confident that you only get the genuine article.

Your trusted borosilicate glass supplier

In a world where precision and quality matter, Cambridge Glassblowing stands as the beacon of excellence in borosilicate glass manufacturing. Whether you need laboratory glassware, borosilicate glass tubes, or specialized glass products, we have the expertise, experience, and commitment to deliver.

For inquiries or to explore our wide range of borosilicate glass solutions, please don’t hesitate to contact us today. Elevate your projects with Cambridge Glassblowing as your manufacturer of borosilicate glass – where innovation meets glass craftsmanship.